1. Description:

Cheese puffs extruder adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2. Raw materials: adopts corn, rice, wheat, oat, barley etc as ingredients

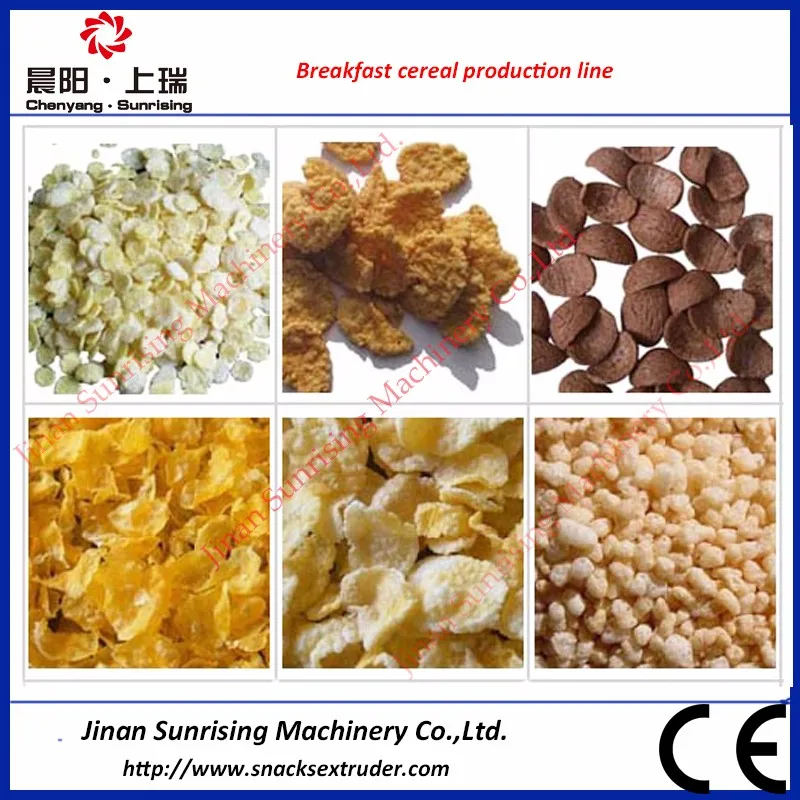

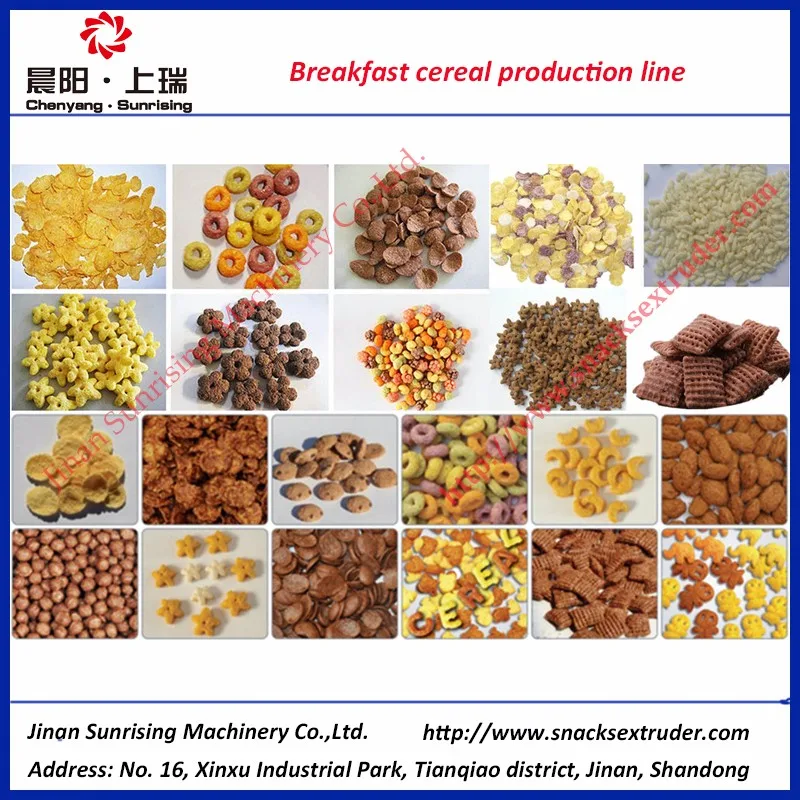

3. Products: Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

4. Capacity: 150kg/h, 240kg/h, 500kg/h

5. Flow chart: Mixing system---Extrusion system---- -Drying system----Flavoring system---Packing system

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

7. Machines Materials:

All the machines are made by stainless steel

8. Technical Parameters

Model

|

Installed power

|

Real power

|

Output

|

Dimension

|

CY65

|

81.5kw

|

53kw

|

100-150kg/h

|

21000x1200x2200mm

|

CY70

|

115kw

|

76kw

|

200-240kg/h

|

23000x1500x2200mm

|

CY85

|

160kw

|

117kw

|

400-500kg/h

|

28000x3500x4300mm

|

No comments:

Post a Comment