Dog food extrusion machine/ Dog biscuit machine/Dog food machine

Introduce:

Dog food making machine can make dog food which is made of many kinds of different materials with scientific configuration and extrusion in the extruder.

Dog food making machine can make dog food which is made of many kinds of different materials with scientific configuration and extrusion in the extruder.

This kind of product can be made into a variety of shapessuch as stick, bone, etc. This kind of food not only provides nutrition to dogs, like protein, fat, vitamin, etc,

but alsosatisfies the dog nature hobby, benefits its strong teeth, cleans mouth and teeth, and prevents disease The final products with fashion shape, special taste,

scientific nutrition combinative, easily to absorb and is quite popular to the pet market.

Materials: adopts corn flour, bone meal, fish meal as raw materials

Capacity: (CY65)120-150kg/h ; (CY70) 160-200kg/h ;(CY85) 300-500kg/h

Process :Mixer---Screw conveyor---Double screw extruder--- Air conveyor--- roasting oven------Hoister---Flavoring---Cooling

Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

Technical Parameter:

Model

|

CY65-II Pet food processing Line

|

CY70 Pet Food Processing Line

|

CY85 Pet Food Processing Line

|

Installed Capacity

|

70 kw

|

120 kw

|

145 kw

|

Power

|

22kw

|

30 kw

|

90 kw

|

Capacity

|

120-150kg/h

|

160-200 kg/h

|

300-500kg/h

|

Dimension

|

12000x1200x2300mm

|

33000x1500x2400mm

|

35000x1500x2500m

|

Detailed information about the line

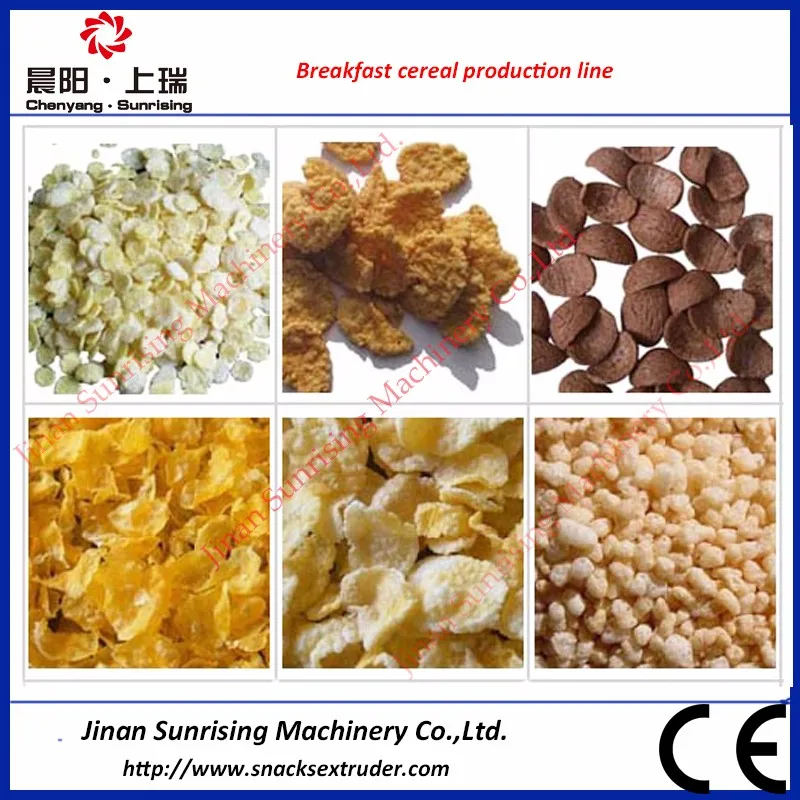

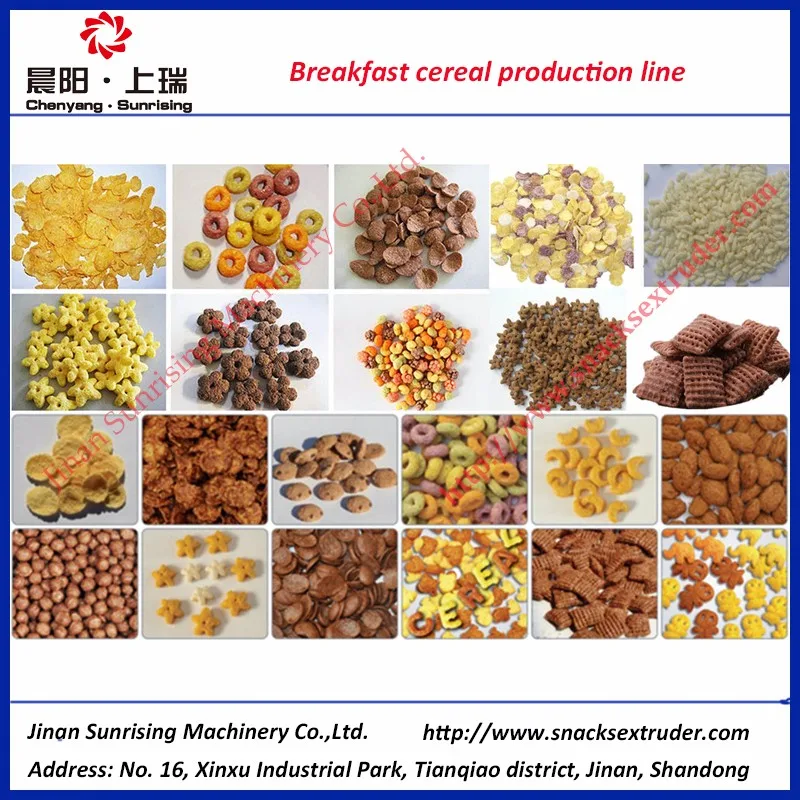

Dog food samples:

Plant pictures:

About installation and after-sale service system:

1. We can provide factory layout according to customer’s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa

when the food processing line arrived your country, and we will send two engineers to go and help you

to install the food line, teach your worker(3-4 workers) how to operate the food line, until your worker know the food line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw,

how to change barrel etc. and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the food and help customer to produce good quality food according customer’s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;